KoVir

Motivation

The continuous improvement process (CIP) is a well established

method for short-time improvements of manufacturing systems and processes.

The central idea of the CIP is to take direct advantage of the worker’s expertise

by integrating them into the improvement process. On a regular basis,

a CIP workshop is arranged where workers can report on bottlenecks in the

production and solutions are elaborated.

Many activities of a workshop, such as analysing current manufacturing processes

or identifying improvement potentials, are performed within the physical

working environment. This impairs the ongoing production process and may

cause unwanted production downtime. A promising approach is to decouple

the elaboration and evaluation of improvement measures from the ongoing production

using the Virtual Reality-technology (VR). This way, flaws can be

avoided and multiple variants can be compared before the expensive process of

implementing changes on the production line is started.

The project

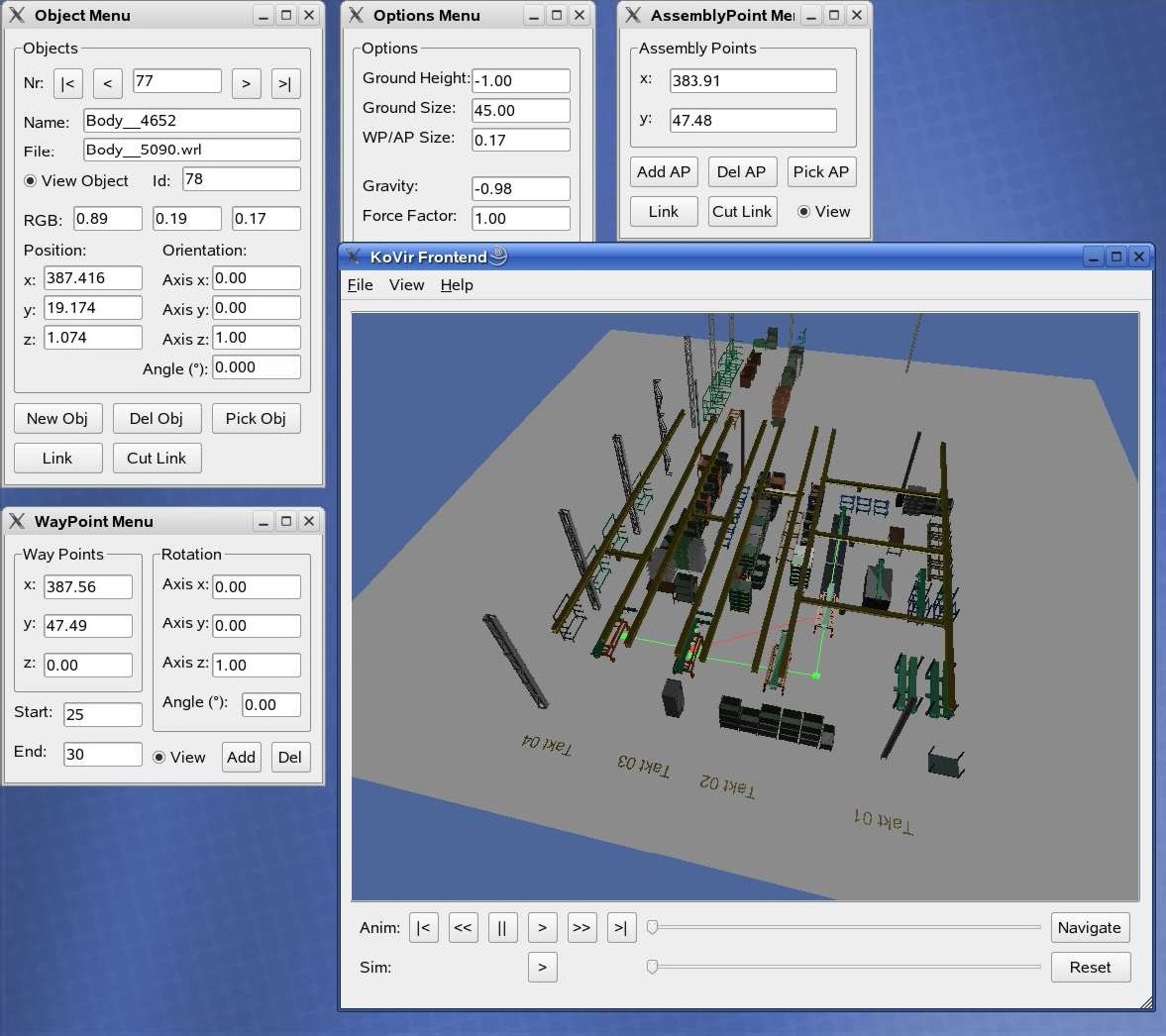

We presume that we have a detailed model of the hall and the

assembled product in Virtual Reality Modeling Language (VRML). In a first

step we reorganize this data in order to make it fit for the virtual CIP. The

reorganization includes an instanciation of similar objects and the creation of

a masterfile in a new XML-based format. If necessary we can simplify the meshes

with a method based on QSlim in order to increase performance.

Then we load the refined data into the KoVir Frontend. This is a powerful

tool in which we can easily reproduce the existing assembly line, through the

use of a novel product assembly graph. This graph contains (but is not limited

to) the following information:

Then we start optimizing the assembly line by trying out changes in the layout

of the hall and the assembly process. We visualize the improvements by playing

animations or physical simulations on a laptop or a personal computer in a first

step. If we feel that there are still improvements that can be done, we restart

with optimizing the hall and the process. If we are satisfied with the results

on the desktop computer, we export the assembly line to a Virtual Reality

environment for further evaluation.

In this step we can integrate the workers directly in the virtual assembly process and test the solutions. If the workers still report bottlenecks we can go back to the optimization step and apply the changes suggested by them. The elaboration of solutions on the desktop computer and the transfer to the Virtual Reality environment work very fast, so that there are no big waiting times and several approaches can be tested in one CIP-workshop. Finally when we are satisfied with all simulations on the personal computer and in the VR environments we can implement the changes into the real world assembly line.

Current status

I am no longer working on this project. You may download the

project thesis

and the master thesis

on this site. My work may be continued by the

University of Kaiserslautern or

John Deere Werke. Please contact them for further information.